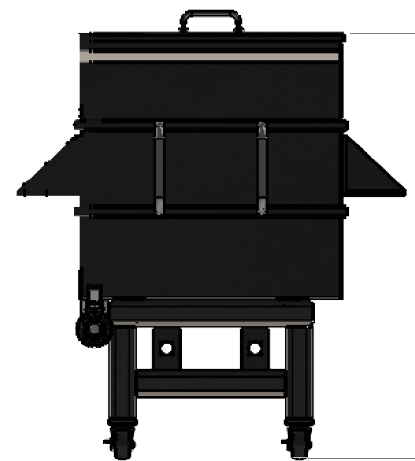

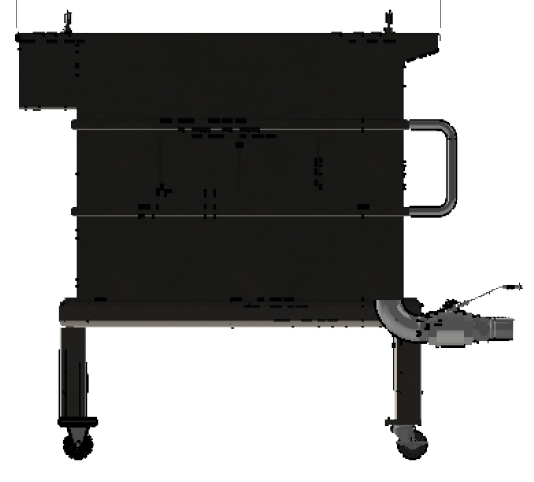

Removable Material Vat with Lid

The Removable Material Vat is installed in the printer and holds the material required for the printing process. The Removable Material Vat can hold up to 140 L (36.98 gal) of material. The Removable Material Vat was designed to allow you to quickly switch materials between prints by removing one material vat and quickly replacing it with a spare material vat. A spare Removable Material Vat is available for purchase.

|

|

|

Removable Material Vat Front View |

Removable Material Vat Side View |

|

Dimensions (full vat)

|

Footprint: 78.31 x 71.93 x 78.61 cm (30.83 x 28.32 x 30.95 in)

Shipping dimensions: 83.82 x 88.9 x 76.2 cm (33 x 35 x 30 in)

|

|

Weight

|

Unit: 83.46 kg (184 lb)

Shipment: 96.16 kg (212 lb)

|

|

Electrical

|

N/A

|

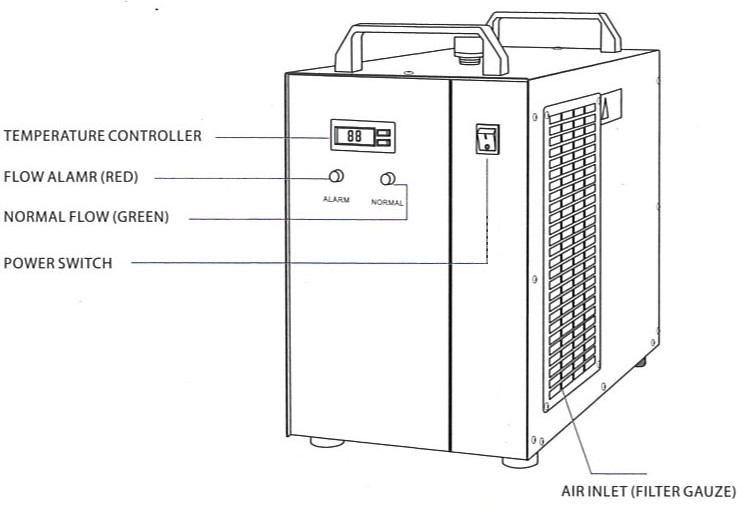

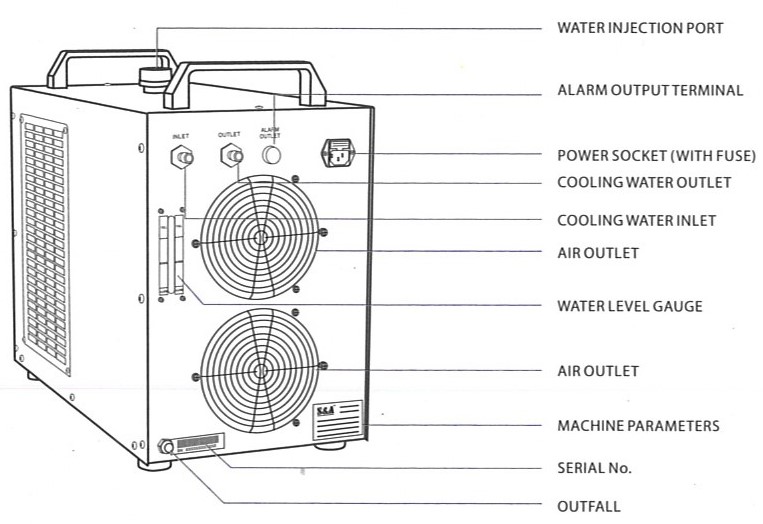

Industrial Chiller

The Industrial Chiller is a compressor-based refrigeration chiller that can achieve a cooling capacity of up to 1800W. The industrial chiller is required to maintain proper operating temperature for the Xtreme 8K™’s projector. The chiller connects to the Xtreme 8K™ and must be installed within 121.90 cm (48 in) of the printer.

The industrial chiller requires coolant to operate and has a tank capacity of 10 L (2.64 gal).

Industrial Chiller Front View

Industrial Chiller Rear View

Industrial Chiller Clearance

The industrial chiller requires a minimum amount of space for operation, maintenance, and heat dissipation.

-

A minimum of 150 cm (59.05 in) behind the chiller (exhaust air).

-

A minimum of 100 cm (39.37 in) to the right and left of the chiller (inlet air).

|

Dimensions

|

Footprint: 59 x 38 x 74 cm (23.23 x 14.96 x 29.13 in)

Shipping dimensions: 67 x 51 x 93 cm (26.38 x 20.08 x 36.61 in)

|

|

Weight

|

Unit: 44 kg (97 lb)

Shipment: 50 kg (110.23 lb)

|

|

US Version

|

Universal Power Version

|

|

|---|---|---|

|

Voltage

|

AC 1P 110V

|

AC 1P 220V

|

|

Frequency

|

60Hz

|

50/60 Hz

|

|

Current

|

0.45~7.5A

|

0.25~3.9A

|

|

Machine Power

|

0.71kW

|

0.86kW

|

|

Refrigerant charge

|

350 g

|

480 g

|

Accessories

![]() WARNING

WARNING

Fire hazard: Note that if IPA is used for washing, the equipment must be certified for use with flammable liquid and Washing Unit manufacturer instruction for classification of surrounding areas must be respected.

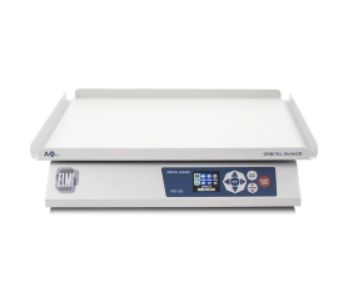

Orbital Shaker

One option for a large parts washing solution is an Orbital Shaker with:

-

a maximum greater than or equal to 200 RPM,

-

an amplitude greater than or equal to 20 mm (0.79 in), and

-

a platform size of at least 300 x 200 mm (11.81 x 7.87 in).

A plastic container will need to be purchased separately. The platform size with the container will determine the maximum allowable part size.

Ultrasonic Cleaner

A second option for a large parts washing solution is an Ultrasonic Cleaner with:

-

a frequency between 37-40 Hz,

-

power/volume greater than or equal to 18W/L, and

-

a tank size greater than or equal to 327 x 300 x 200 mm (12.87 x 11.81 x 7.87 in).

The tank size will determine the maximum allowable part size.

Drying, Thermal Curing, and Annealing Oven

The Shop System Drying Oven from Desktop Metal is recommended for all drying, thermal curing, and annealing purposes.

Shop System Drying Oven Front View

|

Dimensions

|

Product: 110 x 107 x 74 cm (43.31 x 42.13 x 29.13 in)

Shipment: 140 x 120 x 120 cm (55.12 x 47.24 x 47.24 in)

|

|

Weight

|

Oven: 116 kg (255 lb)

Shipment: 166 kg (365 lb)

|

|

Electrical

|

240 V, 12.7 A (15A or above circuit), 50/60 Hz, 3 kW

|

|

Plug type

|

NEMA 6-15P or IEC Type F Plug

|

|

Noise level

|

Estimated operational maximum: 80 dB(A) @ 1m

|

|

Heat load

|

Operational maximum: 3 kW (10,236 BTU/hr)

|

|

Exhaust

|

Flow (adjustable): 9.4-23.6 Lps (20-50 CFM)

Maximum temperature: 200°C (392°F)

Connection type: 10.2 cm (4”) Diameter duct

Condensate trap: Trap to prevent condensate from flowing into oven exhaust. Use T fitting or similar.

|

Curing Unit

The UVCA 3000 UV is the UV light flood lamp for the post-processing of UV sensitive curing materials for industrial and consumer goods applications. This final step after 3D printing and cleaning a printed part results in higher strength and stability as well as ensuring a thorough cure. The UV Light Curing Box for Xtreme 8K™ includes a rotating inner table to maximize exposure of all parts of the model to the UV light.

UVCA 3000 Front View

|

Dimensions

|

Product: 71.12 x 88.9 x 71.12 cm (28 x 35 x 28 in)

Shipment: 93.98 x 106.68 x 101.6 cm (37 x 42 x 40 in)

|

|

Weight

|

Curing unit: 83.9 kg (185 lb)

Shipment: 115.67 kg (255 lb)

|

|

Electrical

|

120-240V, 1 ph, 50/60Hz, 3A

|

|

Model Size (maximum)

|

86.4 x 68.6 x 66 cm (34 x 27 x 26 in)

|

|

Front Loading Door Size

|

60.9 x 45.7 cm (24 x 18 in)

|

|

Viewing Window Size

|

12.7 x 12.7 cm (5 x 5 in)

|

|

Turntable Speed

|

2 RPM

|

|

Turntable Plate Diameter

|

48.3 cm (19.5 in)

|

|

UV Source

|

UV lamp, quantity: 9

|