![]() WARNING

WARNING

Risk of injury: The use of the materials intended for the printer may cause risks to the health and safety of the operator or third persons. To ensure safe handling of the materials, the hazard and precautionary statements shown in SDS must be observed.

![]() CAUTION

CAUTION

Risk of injury: As handling chemicals puts you at risk of coming into contact with corrosive chemicals, being burnt, inhaling poisonous vapors, etc., always put on suitable protective clothing (nitrile gloves, protective goggles) before working with construction substances.

Take utmost care to avoid getting any chemicals in your eyes or breathing the chemical vapors in.

Always wash your hands thoroughly afterwards with soap and water only. Don't use Isopropyl alcohol to wash your hands if come in contact with materials. Be careful not to spill chemicals.

NOTICE

Do not use materials other than the photopolymers delivered by ETEC™. Read the relevant Material Safety Data Sheets supplied with the materials before use.

Temperature controllers heat the chamber, blade, and material tank inside the printer. Once the Xtreme 8K™ CS is started, the system initiates heating the chamber, blade, and material tank to the predefined temperatures.

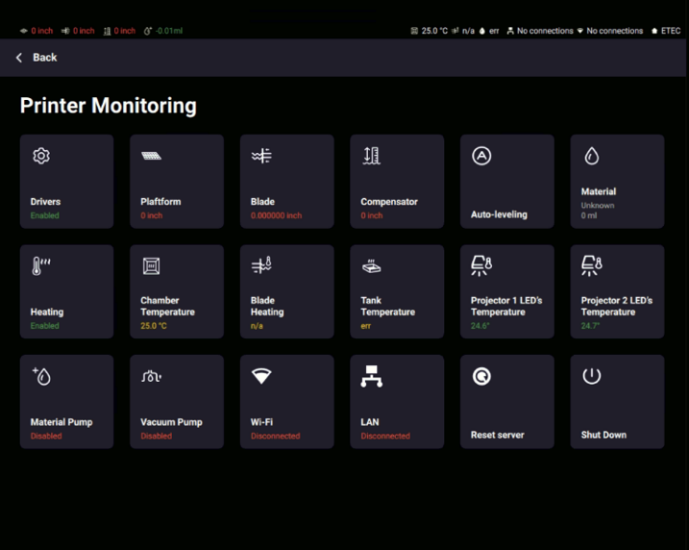

Information about the temperature changes is displayed on the status bar at the top of the window and in the Printer Monitoring menu.

When print job starts, the system detects the required temperatures for the chamber, blade, and material tank and heats the components to the minimum required temperatures indicated in the job file. There is an option to abort the job during the printing process.

When the minimum required temperature is established, the printing begins. The printer continues to maintain the target temperature during the print job.

If the chamber, blade, and material tank do not reach the required temperature then the job will not start.